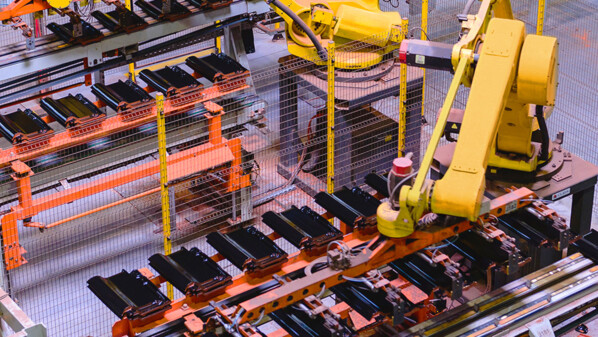

Production Process

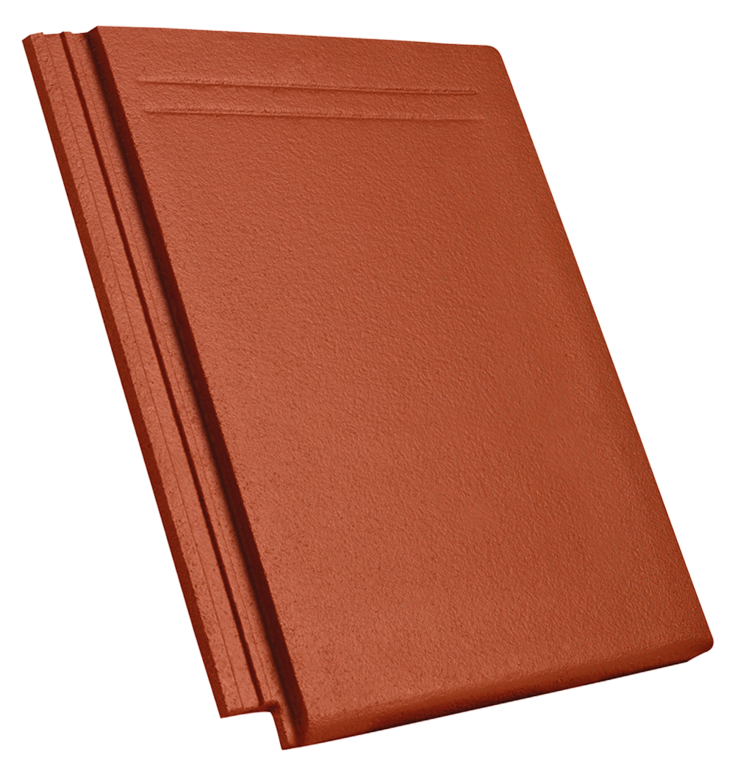

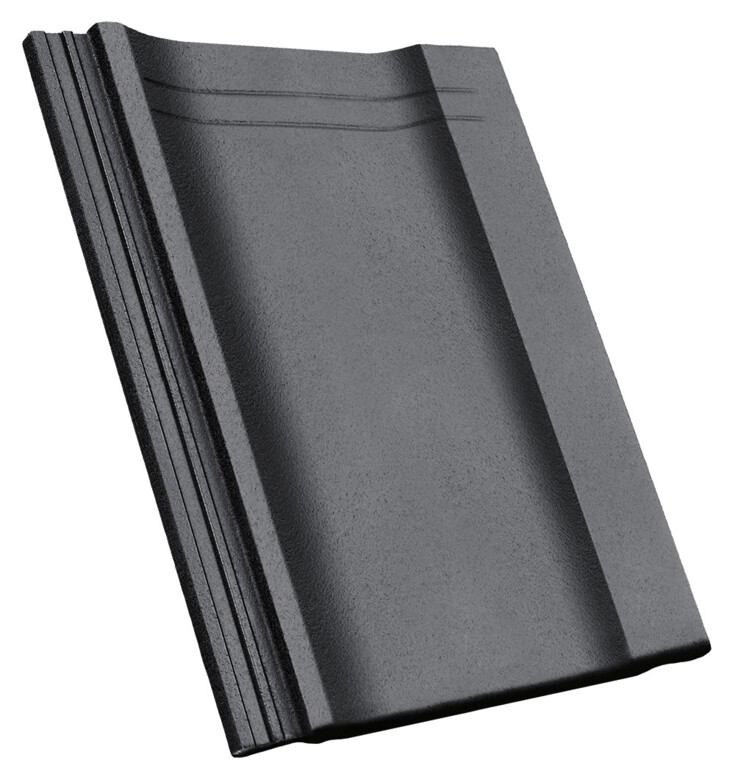

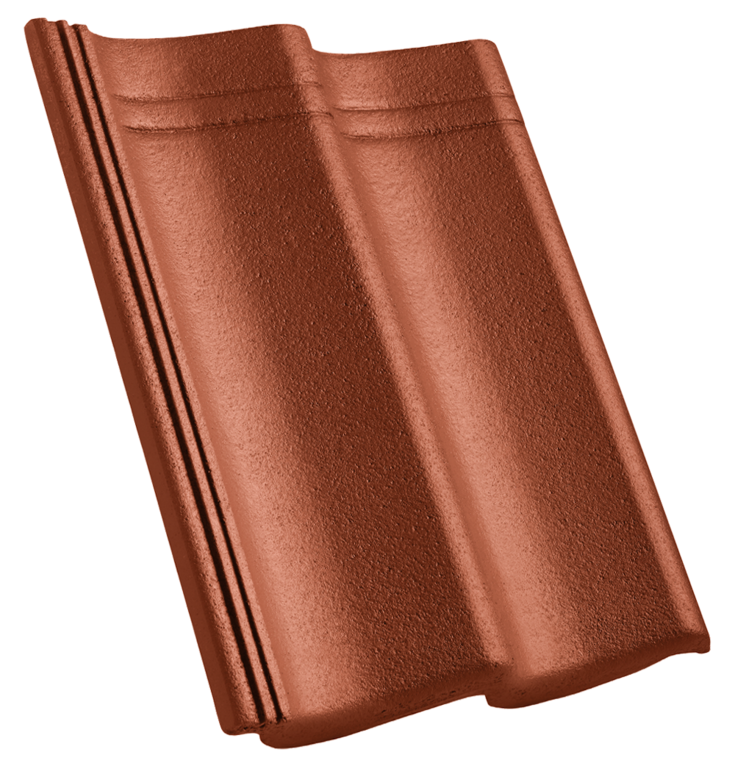

swissporTON Roof Tiles i Innovation, Durability, and Beauty on Your Roof

Dreaming of a roof that combines reliable protection, exceptional aesthetics, and an eco-friendly approach? Discover swissporTON ceramic and cement roof tiles – the result of advanced technology and a passion for creating solutions that last for years, delighting with their appearance. At swissporTON, we know the roof is the heart of your home, which is why we focus on quality visible in every detail.